Preparing for a factory relocation can seem overwhelming. While it definitely can be, it doesn’t need to be! Our factory relocation checklist is here to ease your worries. As you check each box, we want you to feel that weight of the world leaving your shoulders. After you’ve read over this guide and you’re thinking, “Wow this still seems like too much” – just reach out to us, and we’ll handle it from here.

What Does a Factory Relocation Entail?

Relocating a factory means moving heavy equipment, organizing logistics, and managing timelines. It’s a meticulous process that demands careful planning and execution. With a factory relocation, it’s important to keep up with what’s done, and what needs to be done, all the while keeping everyone and everything safe. Hiring or building a diverse team, preparing for supply chain issues, and scheduling everything takes a long time. We estimate you’ll spend around 120 days and around 225 hours planning and executing a move. That’s why we recommend planning your move with plenty of extra time – at least 6 months out. Whether it’s the factory floor setup, manufacturing processes, energy efficiency, or overall design of the warehouse, be sure to seize any opportunity to implement money-saving measures.

Factory Relocation Checklist

- Start planning your move early – around 6 months out

- Choose the right team for your factory move

- Contact any contractors you may need

- Engage with your staff about the move

- Prepare new and old factory layout drawings

- Audit machinery and plan for necessary repairs or replacements

- Have safety measures in place

- Consider how the move will affect the supply chain

- Develop a detailed schedule that aligns with your goals and minimizes downtime

- Draft comprehensive instructions for disconnecting, transporting, and reinstalling machinery, as well as site cleanup.

- Recognize improvement opportunities for your factory layout and how it can be improved

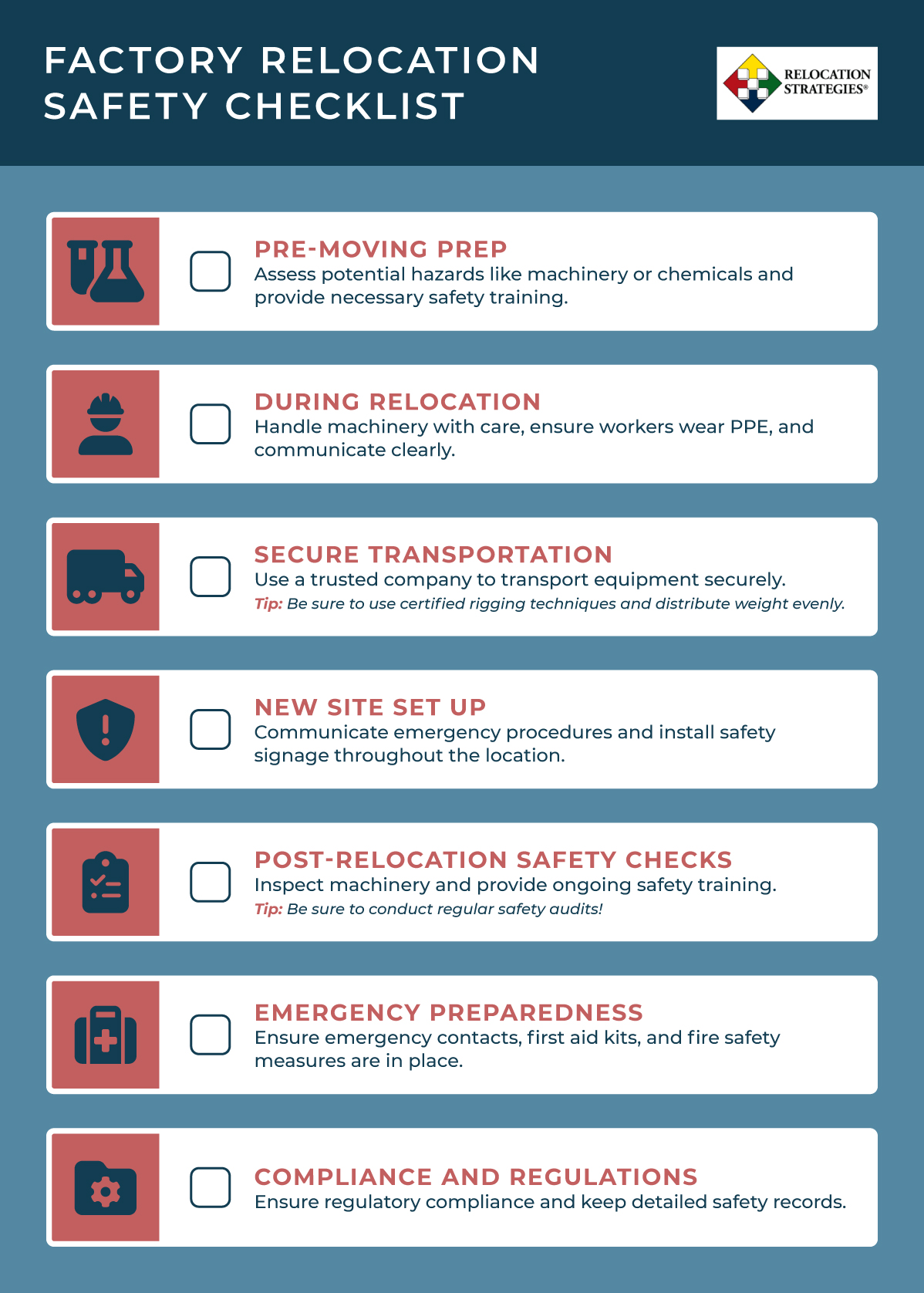

Factory Relocation Safety Checklist

The Importance of Safety When Moving a Factory

The significance of relocating a factory safely is crucial. The most important is the well-being of everyone involved, from contractors to employees. Another important reason to put safety measures in place is to keep the environment healthy. Here are all the reasons to safely move your factory:

- Protecting Lives: Safety measures are paramount to safeguarding the well-being of everyone involved – from employees to contractors. Prioritizing safety ensures we all stay safe and sound throughout the process.

- Environmental Safety: By implementing environmentally friendly practices, such as proper waste management, pollution prevention, and energy efficiency measures, we minimize our environmental impact during the relocation process.

- Minimizing Risks: Moving heavy machinery and handling hazardous materials requires careful attention to safety. By identifying and addressing potential hazards, we reduce the risk of accidents.

- Preserving Assets: Factory equipment is valuable, and proper handling can help protect these assets from damage or loss during the move.

- Maintaining Productivity: Safety incidents can disrupt workflow and productivity. By prioritizing safety, we minimize disruptions and keep operations running smoothly.

- Compliance and Liability: Complying with safety regulations and standards is vital to avoid fines and legal liabilities.

- Protecting Reputation: By prioritizing safety, you showcase your commitment to the well-being of our employees, customers, and stakeholders, enhancing trust in your brand.

Make Moves with Relocation Strategies

So, you’ve read the guide, how are we feeling? If you feel like you are ready to tackle this on your own, here’s a free downloadable checklist for your office operations, just to get you started. If you think there may be way more to factory relocation than you thought, reach out to us today. We handle everything from A to Z.